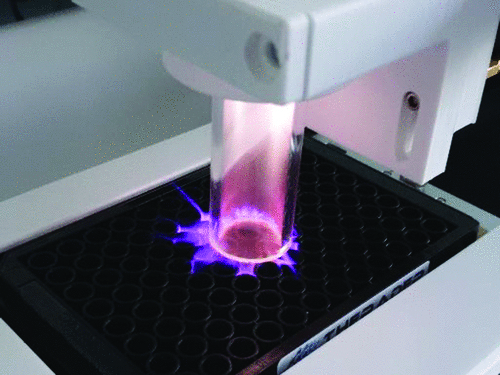

Researchers utilized a cold atmospheric plasma unit to deposit collagen onto 96-well polystyrene plates. The coatings were applied using a variety of power settings to evaluate how plasma intensity influenced the structural integrity and viability of the protein. The team performed plasma characterization through voltage, current, and power measurements, while the resulting coatings were assessed using gravimetric analysis, cell growth studies, and water contact angle measurements. Spectroscopic analysis was also used to compare these surfaces to established commercial products. Results confirmed that the plasma-deposited coatings matched the performance of commercial plates while significantly reducing both production time and cost. This technique represents a viable pathway for the automated inline manufacturing of collagen-coated labware.